Vibratory stress relief

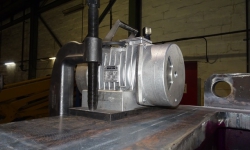

The production, processing and deformation of metallic workpieces can result in undesirable stresses. These are usually reduced by stress-relief annealing. With the latest generation of VIBMATIC®8000 units, Bock Maschinenbau GmbH possesses a very good and proven alternative to stress-relief annealing.

We can treat workpieces from 100 kg to 200 t through vibratory stress relief. With this newly acquired processing capability, we are able to significantly increase the quality of our products.

Vibratory stress relief requires less energy, which significantly reduces CO² emissions. This eliminates the need to descale the workpieces and avoids the distortion caused by annealing.

Of course, you will receive a production log for each component that we vibrate without any waiting time. We are also happy to offer vibratory stress relief as a service at our factory. Or by our trained staff at your premises. We are not bound to any "annealing days" and can react flexibly.

Advantages at a glance:

- Shorter delivery times

- Significant reduction in CO² emissions

- Improve quality

- Vibrate on site with you

- Production logs without waiting times

- Flexibility

- No annealing distortion

- No descaling